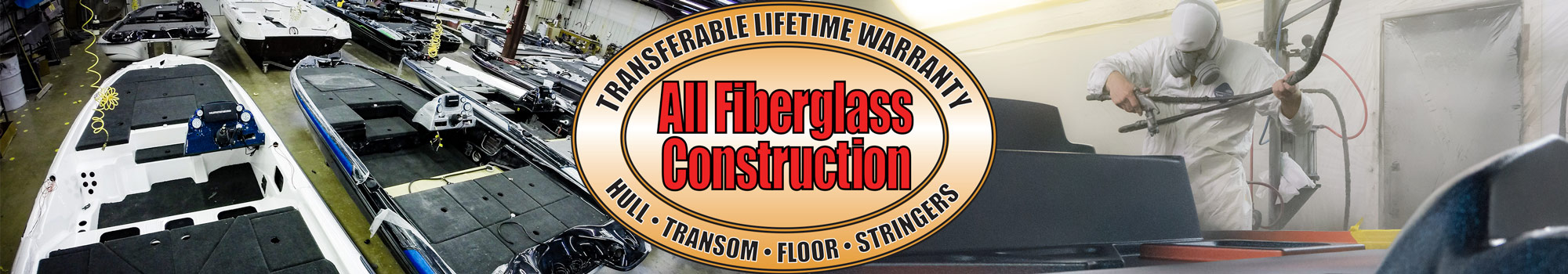

Our construction techniques are not only innovative, they are revolutionary. We stand behind each boat with a transferable lifetime structural warranty. The Pierce family is not the new kid on the block when it comes to building premium fiberglass fishing boats. We’ve been leading the pack since 1971!

View the Bass Cat Factory Tour video series HERE

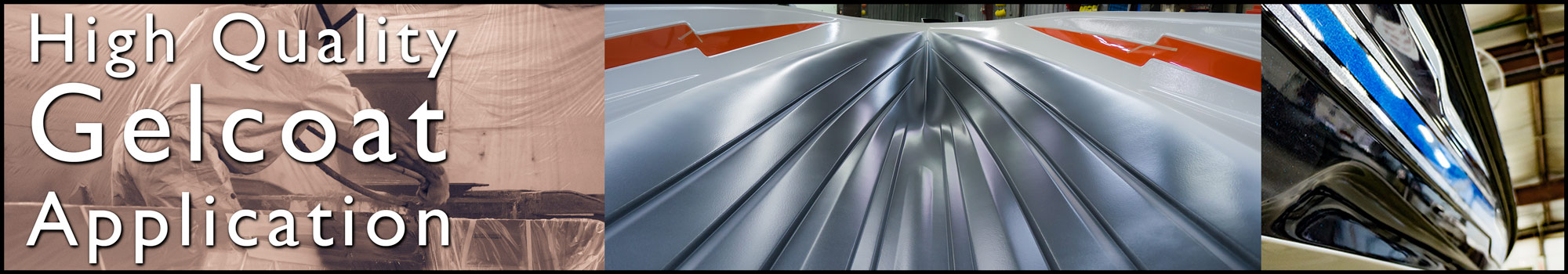

It all starts with a painstaking hull prep and gel coat application. Specific pressures with our premium gel coat produces the deep finish and clean lines our customers have come to expect.

Our full width transom is the absolute strongest transom in the industry. It’s a thick, vacuum molded part that can handle many season of rough water use. Once that part is completed, it’s set into wet fiberglass for superior support.

Our lamination schedule, evolved over time, sets a foundation of strength unmatched in the bass boat industry. A large portion of our team has decades of experience behind them, and it truly shows over the lifespan of our boats.

The term “One-Piece” is an overused term in our industry that few can back up. The hull, floor, custom one-piece stringer assembly, and transom are literally sucked together using huge vacuum pumps for a bond that earns the one-piece name. This bonding process offers increased durability, energy transfer, and performance characteristics that our boats have become famous for.

Attention to detail is a priority in the finishing department. Every piece of hardware is countersunk into our boats, steering cables fully sheathed, dashes are drilled to fit. On the showroom floor, many of our finishing touches go unnoticed. It’s throughout your many years of ownership that these qualities eventually shine. Take some time to view our finishing video HERE, and see why we provide a total commitment, with no compromise here at Bass Cat.

Our construction techniques are not only innovative, they are revolutionary. We stand behind each boat with a transferable lifetime structural warranty. The Pierce family is not the new kid on the block when it comes to building premium fiberglass fishing boats. We’ve been leading the pack since 1971!

View the Bass Cat Factory Tour video series HERE

It all starts with a painstaking hull prep and gel coat application. Specific pressures with our premium gel coat produces the deep finish and clean lines our customers have come to expect.

Our full width transom is the absolute strongest transom in the industry. It’s a thick, vacuum molded part that can handle many season of rough water use. Once that part is completed, it’s set into wet fiberglass for superior support.

Our lamination schedule, evolved over time, sets a foundation of strength unmatched in the bass boat industry. A large portion of our team has decades of experience behind them, and it truly shows over the lifespan of our boats.

The term “One-Piece” is an overused term in our industry that few can back up. The hull, floor, custom one-piece stringer assembly, and transom are literally sucked together using huge vacuum pumps for a bond that earns the one-piece name. This bonding process offers increased durability, energy transfer, and performance characteristics that our boats have become famous for.

Attention to detail is a priority in the finishing department. Every piece of hardware is countersunk into our boats, steering cables fully sheathed, dashes are drilled to fit. On the showroom floor, many of our finishing touches go unnoticed. It’s throughout your many years of ownership that these qualities eventually shine. Take some time to view our finishing video HERE, and see why we provide a total commitment, with no compromise here at Bass Cat.